CNC Milling Service

Custom CNC Milling Services for Milled Plastic and Metal Parts, Global Delivery within Days.

Our CNC Milling Solutions

Clever Mould is a professional provider of CNC machining services with advanced 3-, 4-, to 5- axis milling centers. We offer custom CNC milling for various industries worldwide. Our precision 3-, 4- and 5-axis CNC milling centers and experienced team guarantee our incredible CNC capacity, enabling us to handle the whole stage of the milling process easily from designing, prototyping, manufacturing, to final transportation.

With excellent capabilities and extensive expertise, we can provide top-grade but cost-effective custom CNC machining services from China, including 3-, 4-, and 5-axis milling for high-speed CNC manufacturing and rapid prototyping, and precision CNC turning. Our high-quality milled products are involved in the field of automation design, machine tool machining, medical equipment, lighting parts machining, etc.

What Is CNC Milling

CNC milling is cutting solid plastic or metal material into final precision parts using different axis milling processes. Unlike CNC lathes, CNC mills remove material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and position the workpiece properly, to create a finished or semi-finished shape.

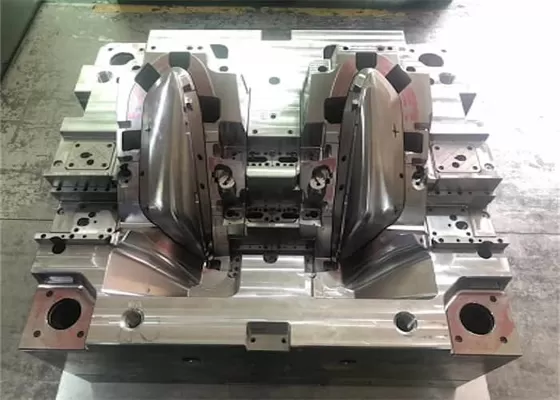

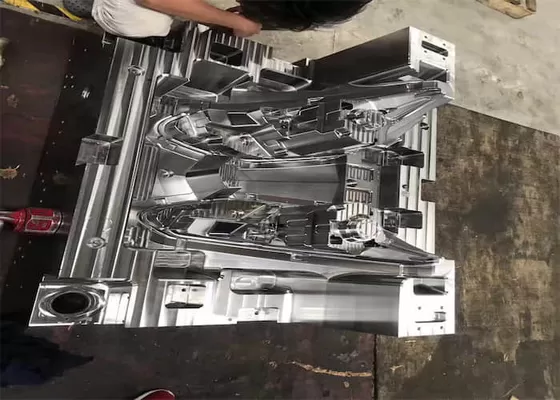

The multi-axis milling machines realize a versatile, accurate, and repeatable CNC milling process for the production of different features and complex geometries. Take channels, holes, curves, and corners for some examples. Milling can be also used as a perfect way of making tooling for die casting and injection molding.

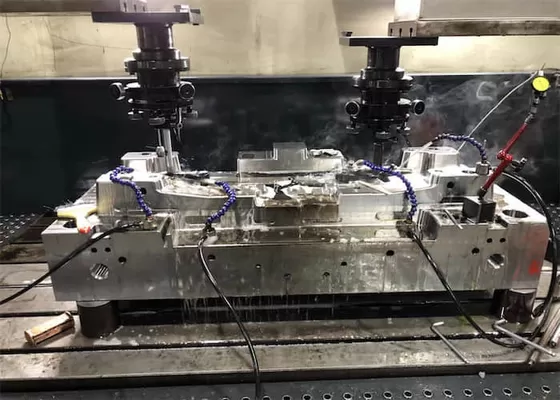

Our advanced facilities conclude imported 3-axis, 4-axis, and 5-axis CNC mills that are equipped with different tool sets to maximize production efficiency and speed. Send us your inquiry or 3D files online to get an online quote for free now.

How Does CNC Milling Work

The first step is using CAD software to design a part with desired geometry. Then you can submit your 3D CAD files online and get an instant quote for free. Upon all details having been checked and determined, your digital design will be put into production immediately.

- Design a 3D CAD model

- Convert the CAD model into the CNC machine program

- Start the machining process through the interface or control panel

- Remove block material from the workpiece to get desired shapes

- Conduct the CNC milling operation with high precision

Why Choose CNC Milling

CNC Milling Materials Options

We provide more than 50 types of plastics and metal blocks with different specifications for CNC milling.

Pthermosets, Thermoplastics, PP, PE, PVC, etc.

Plastic CNC milling is generally viewed as the most economical way to make rapid prototypes and carry out functional testing of designs.

Aluminum, steel, brass, copper, stainless steel, zinc, titanium, etc.

CNC milling is a preferable method for both rapid prototyping of metal parts and end-use parts.

Ceramics (such as Alumina, AIN, Si3N4, and SiC), rubber, wood, glass, etc.

Other materials like ceramics, rubber, wood, glass, etc are also on our list to meet your CNC milling needs.

CNC Milling Surface Finishes

Without any surface treatment processing methods, the parts will leave visible tool marks and burrs, which can be completed quickly and cost-saving.

A surface treatment process to obtain a certain degree of cleanliness and different roughness on the surface of the workpiece. The surface after sandblasting is dull and matte.

Many colors(such as black, red, blue, etc.)are available. Divided into Type II (normal) and Type III (hard), Type III is usually thicker than Type II and more corrosion resistant.

The powdered paint is sprayed onto the surface of the workpiece by electrostatic spraying to form a powdery coating, and then the powder layer is cured by heating and baking to level it into a uniform film layer. It is usually used for appearance parts, and a variety of colors is available.

Request an instant RFQ and we will offer you the appropriate surface finish for your project if you still do not see the finish you are looking for.

Different Types of CNC Mills

Generally, the type of CNC mills is defined according to their number of axes. With more axes, the ability to manufacture complex parts and create cutting angles is enhanced and strengthened.