Custom Online CNC Machining Service

Online CNC machining service for custom parts, rapid prototyping & production

Our CNC Machining Capability

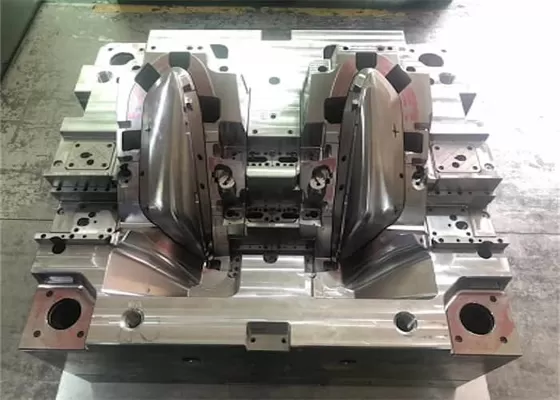

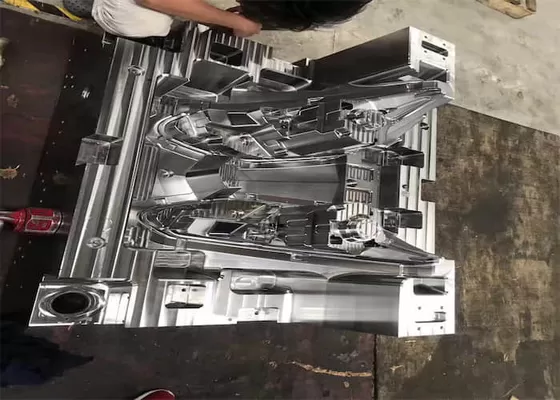

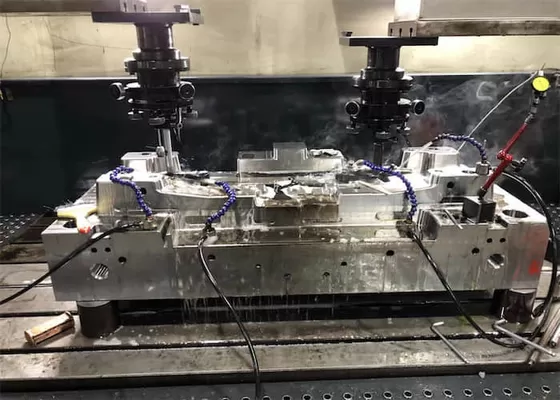

Clever Mould offers a wide range of custom online CNC machining services, including 3, 4, and 5-axis CNC milling and CNC turning, grinding, EDM, laser cutting, and others. There are abundant CNC machining services from design, rapid prototyping, and complex parts geometry to low or large-volume production for your choice. And we are always committed to producing high-quality machined parts in line with your budget and lead time demand. Think about Clever Mould if other CNC machine shops have no capability to complete your high-standard components.

CNC Machining Processes

CNC Turning

CNC turning is a process of machining parts with cylindrical features from metal or plastic rod stock. This process allows to make any circular parts effectively such as shafts, worms, and spheres, and it can apply to the creation of parts with complex external and internal geometries and various threads.

CNC Machining Materials & Finishes

Choosing the exact materials and surface finishes is a vital step in the manufacturing of your CNC machining projects. Headquartered in China, more than a CNC shop, we are also a reliable supplier who stocks all kinds of materials and offers various finishing options on your demand.

Materials

Aluminum 6061

Aluminum 5052

Aluminum 2024

Aluminum 6063

Aluminum 7050

Aluminum 7075

Aluminum MIC-6

Copper 101

Copper C110

Copper 260

Copper 360

Nitronic 60 (218 SS)

Stainless Steel 15-5

Stainless Steel 17-4

Stainless Steel 18-8

Stainless Steel 303

Stainless Steel 316/316L

Stainless Steel 416

Stainless Steel 410

Stainless Steel 420

Stainless Steel 440C

Steel 1018

Steel 1215

Steel 4130

Steel 4140

Steel 4140PH

Steel 4340

Steel A36

Titanium (Grade 1)

Titanium (Grade 2)

Titanium (Grade 5)

POM (Delrin/Acetal)

ABS

Polyethylene

Nylon (Polyamide)

PLA

PC

PEEK

PMMA (Acrylic)

PP

PTFE (Teflon)

Polystyrene

PVC

PEI

CF

Finishes

As machined: Without any surface treatment processing methods, the parts will leave visible tool marks and burrs, which can be completed quickly and cost-saving.

Bead Blasting: A surface treatment process to obtain a certain degree of cleanliness and different roughness on the surface of the workpiece. The surface after sandblasting is dull and matt.

Anodizing: A process of forming a layer of oxide film on aluminum products, to overcome the defects of aluminum alloy surface hardness and wear resistance. Many colors(such as black, red, blue, etc.)are available. Divided into Type II (normal) and Type III (hard), Type III is usually thicker than Type II and more corrosion-resistant.

Powder coating: The plastic powder is adsorbed to the surface of the workpiece by electrostatic spraying to form a powdery coating, and then the powder layer is cured by heating and baking to level it into a uniform film layer. It is usually used for appearance parts, and a variety of colors is available.

CNC Machining Tolerances

Our standard tolerance for metal is DIN-2768-1-f and plastic is DIN-2768-1-m in CNC machining. The tolerance is greatly influenced by the part’s geometry and material type. For the specific tolerance details of different parts, please contact us.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

Why Choose Us

Our custom CNC machining service is faster, easier, and more affordable than traditional machine shops using automation.

- Instant quotes within 24h – no need to keep track of quotes in your mailbox;

- No demands for a minimum order volume – no limits on the order size & dollar value;

- Transparent pricing – all production costs based on the design are included in our quotes;

- Full Series of Materials – Choose from various alternatives of possible combinations of materials and finishes for your order;

- The ability of unmatched capabilities – overperform the most of our rivals;

- High assured quality by our QA teams- a standardized inspection report with every order;

- Our distribution networks allow each order competitive pricing.