5-Axis CNC Machining Services

Custom 5-Axis machining & milling with world-class precision, Faster cycle time, higher precision, and better quality.

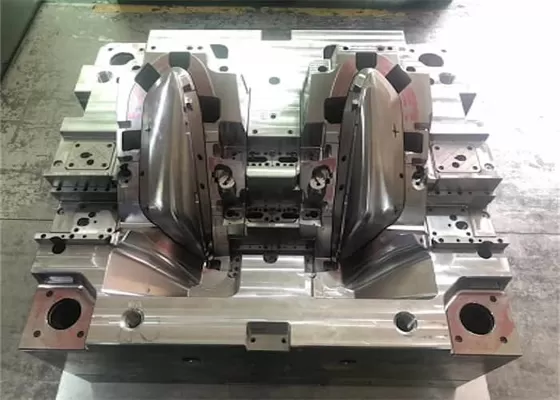

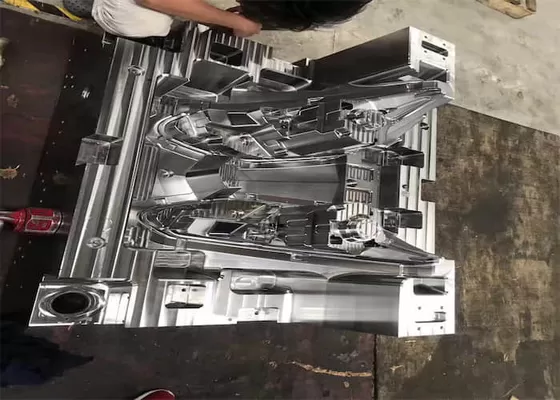

Our CNC Milling Solutions

Whether you require an initial prototype or a complete set of components that are identical to each other, Clever Mould offers exceptional 5-axis machining services to meet your goals within the specified time frame and budget.

For machined parts that are time-sensitive and have intricate geometric shapes, 5-axis CNC machines provide unmatched flexibility and efficiency. The skilled team at Clever Mould can help turn your concepts to life, from rapid prototypes to end-use parts specifically designed for safety-critical applications. Our 5-axis milling abilities allow us to consistently manufacture exceptional parts within a short lead time.

What Is 5-Axis CNC Machining?

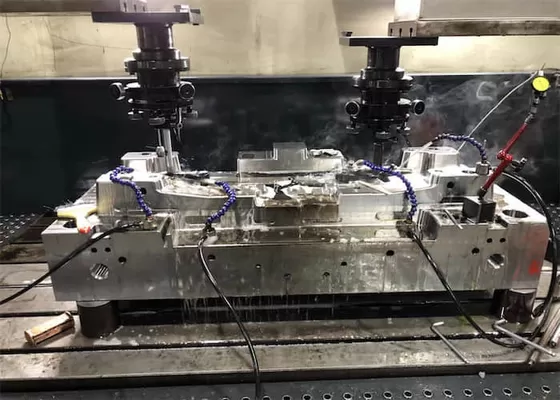

5-axis CNC machining is a manufacturing process that involves using computer-controlled technology to move a machine tool in five different directions. These directions are typically the X, Y, and Z axes for straight movements, and two additional axes for rotation. This type of machining is known for its versatility in handling parts of various sizes and shapes.

To perform 5-axis CNC machining, a machine tool needs a special computer system and software. These allow the operator to input the desired movements and tool paths for machining. The machine may also have additional features like a rotating table, which allows the workpiece to be turned in different directions.

Compared to conventional CNC machining techniques, 5-axis machining centers have several advantages. They eliminate the need for multiple setups, transferring and inspecting parts, and manual handling, which can lead to errors. With 5-axis CNC machining, a workpiece can be machined from different angles with high precision. This method is commonly used in manufacturing complex shapes, intricate parts, and components for industries like aerospace, automotive, medical, and electronics.

Advantages of 5-Axis CNC Machining

Why Choose Clever Mould 5 Axis Machining Services

Work with Clever Mould, you’ll have access to manufacturing experts who are here to help you every step of the way. This ensures that your project is completed with high quality, from the initial concept to the final outcome.

The Best 5-Axis CNC Milling Services With Ultra Precision

One of the primary advantages of 5-axis milling lies in its capacity to fabricate parts with intricate complexity using only a single tool setup. This reduces the necessity for human intervention, ensuring that components are machined with consistent accuracy and in significantly shorter turnarounds. With high flexibility and precision, 5 axis milling makes it possible to manufacture micro-components efficiently and accurately.

At Clever Mould, we have honed our expertise in 5-axis CNC machining to create components considered to be nearly impossible to create. The ability to execute true 5-axis work requires highly remarkable programming and machining skills. The team of manufacturing engineers and machinists at Clever Mould boasts over a decade of extensive experience in the CNC machining field. They exhibit excellent proficiency in operating 5-axis milling centers and delivering optimal outcomes.

.jpg?v=1757395759)